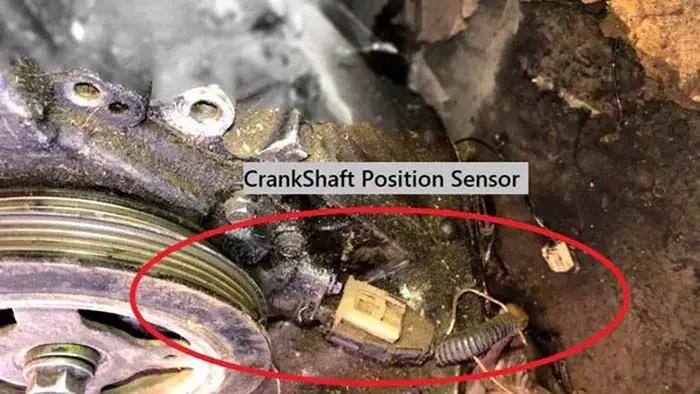

The crankshaft position sensor is one of the most important sensors that are located in your car. It is a multifunctional device that handles many of the important functions of the car to keep running the car smoothly.

The crankshaft position sensor is located in every car with an internal combustion engine either a diesel or a petrol engine.

In this powerful guide, we are going to learn what the crankshaft position sensor is, its working, and its function.

What Is Crankshaft Position Sensor

Before the introduction of the crankshaft position sensor in the market, the cars used to rely upon the distributor, which is used to inject the fuel into the car combustion chamber at specific timings as adjusted by the driver or user.

The crankshaft position sensor is an electronic sensor, which measures the position of the crankshaft. It detects the crankshaft position and sends the signal to the ECU. The ECU then calculates the injection timing, ignition timing, and engine RPM according to the crankshaft position sensor’s signals.

This sensor is used to monitor the speed of the rotation of the crankshaft. The reading of the crankshaft speed of the engine is utilized in different capacities by the engine management system such as managing the timing of the ignition or the amount of the fuel to be injected in the combustion chamber of the car or various other parameters on which the proper running of the car depends upon.

The crankshaft position sensor can also be used along with the camshaft sensor to observe the working relations of the engine pistons with the valves that are installed in the car engine.

This relation between the crankshaft position sensor and the camshaft sensor is quite important in cars that have variable operation timings of the valves of the engine.

This method is also used to synchronize the four-stroke engine upon its starting. It allows the car electronic control unit (ECU) to know the exact time of the fuel injection into the car combustion chamber to start the car in minimum time and with the least effort.

It also makes the starting of the car more efficient and consumes less fuel upon the starting of the car. When you are trying to start the car while the crankshaft position sensor is at fault, it will not send the reading to the car ECU.

The car ECU will think that the engine is OFF, so the ECU will not turn on the fuel injector, fuel pump, and ignition coil. Hence, the ECU will not start the engine while you are trying to start it.

This is an Info

The crankshaft position sensor is also the primary measurement device for the revolutions per minute of the wheel of the car.

Related Post: How Many Crankshaft Sensors Are In A Car

Crankshaft Position Sensors Function

There are numerous functions of the crankshaft position sensor in the normal running of the car, but there are two main functions, which are linked solely to them. These two functions are as follows:

1. Sensing:

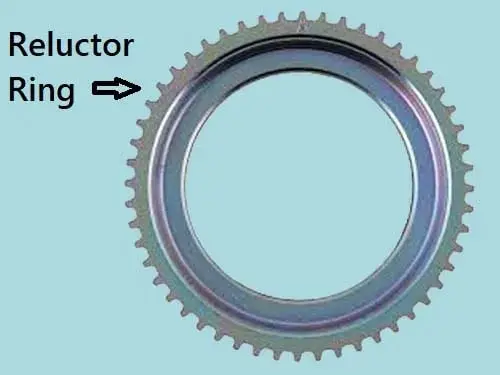

The crankshaft has a powerful magnet sitting right next to it. There is a reluctor’s ring (steel pins) that is arranged at regular intervals all around the crankshaft.

The magnet that is sitting right next to the crankshaft radiates a strong and steady magnetic field. As the crankshaft of the car starts to spin, the reluctor’s ring (steel pins) arranged all around the crankshaft also starts to spin around this strong magnetic field, which causes an alternating current.

This signal is transferred to the electronic control unit (ECU) of the car and the frequency of this signal tells the ECU about the speed of the rotation of the crankshaft.

The ECU uses this data to calculate the position of the crankshaft and decide the timing of the ignition and the amount of fuel injection in the combustion chamber of the engine.

2. Adjustment:

In modern cars, the engine works at the optimal level only when the speed of the movement of the internal parts of the engine is according to the recommendations.

Once the crankshaft position sensor of the car senses the speed of the rotation of the crankshaft in the car’s engine it sends the readings and measurements to the onboard computer of the car, which then uses it to make all the necessary adjustments in the fuel injection and increases its efficiency.

Crankshaft Position Sensor Working

A reluctor wheel is a timing wheel that rides on the back of the crankshaft as it rotates the magnetic sensor is triggered by steel pins in the reluctor’s ring.

The orientation of the crankshaft position sensor is so that the reluctor wheel ring’s teeth that are attached to the crankshaft pass close to the tip of the sensor.

The reluctor’s ring has at least one of the teeth missing, which serves as the reference point for the car ECU to the position of the crankshaft.

The crankshaft position sensor produces its magnetic field. As the movement of the crankshaft starts to spin, the reluctor’s ring arranged all around the crankshaft also starts to spin around this crankshaft sensor’s strong magnetic field.

This rotation around the magnetic field generates an alternating current (AC current) because of the fluctuation or disruption in the field and produces a pulse of voltage and sends it forward to ECU. Every pulse of voltage denotes the teeth of the reluctor’s ring.

This forwarded signal goes directly to the electronic control unit (ECU) of the car. The ECU of the car then utilizes this signal from the crankshaft sensor to decide upon the spark timing in the combustion chamber of the car. The crankshaft position sensor also tells the ECU of the car if there is any misfiring in the combustion chamber of the car.

When there is no tooth of the reluctor’s ring, there would be no voltage sent forward by the crankshaft position sensor to the ECU of the car and this implicates that there would be no injection of the fuel in the combustion chamber of the car because of the absence of the signal from the crankshaft position sensor.

There are two most common types of crankshaft position sensors that are used commonly in the car. One is the magnetic coil pick-up sensor, which produces an alternating current in the coil and the other is the Hall-effect sensor.

The Hall-effect sensor generates the digital square wave signal and sends it to the ECU of the car. Most modern cars use the Hall-effect sensors because of their more accurate readings. The pick-up coil sensors have two connector pins whereas the Hall-effect sensors have three connector pins installed in them.

FAQs

If the crank position sensor is damaged, it can cause a variety of problems. For example, the engine may not start, or it may run erratically. Additionally, the check engine light may come on, and the vehicle may experience reduced fuel economy. In some cases, the damage may be severe enough to cause engine failure.

The crankshaft position sensor is located on the engine block, while the camshaft position sensor is located on the cylinder head. The crankshaft sensor measures the position of the crankshaft, while the camshaft sensor measures the position of the camshaft. The crankshaft sensor is used to determine the position of the piston, while the camshaft sensor is used to determine the position of the valve.

Related Post: Crankshaft Position Sensor Location

Sign Up