A knock sensor is a type of sensor that is used to detect knocking in an internal combustion engine. The knocking noise is caused by the detonation of the fuel-air mixture in the cylinders. The knock sensor is mounted on the engine block and is connected to the engine control unit (ECU). The sensor sends a signal to the computer (ECU) and the computer (ECU) will then adjust the fuel injection and ignition timing to try to reduce the knocking noise.

If there is a problem with the knock sensor, it will not be able to properly detect when knocking is happening and the engine can potentially be damaged. In order to determine if a knock sensor is bad, you can test it in different ways. In this powerful article, you will know how to check if a knock sensor is bad. By performing a simple test, you can save yourself time and money by replacing the sensor before it fails.

Related Post: Top 5 Symptoms Of A Bad Knock Sensor: Don’t Ignore These!

How To Check If A Knock Sensor Is Bad

The knock sensor can be tested and checked for any fault and error in the measurement by different means. When the knock sensor fails, it will usually cause one or more significant symptoms. There are several ways to determine whether the knock sensor is working normally. The steps indicated below must be completed before driving the car; otherwise, the effects may be greater, and the engine may be damaged if the knock sensor is bad.

To check whether the knock sensor is bad or not, different testing techniques can be adopted. But, here we will discuss two fast and easy methods. The first technique includes visual inspection just by checking the parts and observing some precautions. While the second technique includes testing via oscilloscope when the engine is in running condition.

1. By Visual Inspection

I. Checking for Damage in Cable Assembly:

To check for damage in a wire linked with the knock sensor, the cable assembly has to be checked for any damage. Starting from the Engine Control Module to the knock sensor, the wires have to be inspected for faults. Resolve that issue, and check for Diagnostic Trouble Codes, if the problem is still occurring or not.

II. Inspection of DTC (Diagnostic Trouble Codes):

The testing method will be simplified by DTC because it will show each and every defect. The DTC can be identified using OBD – II, which tests each component and makes the diagnosis process simple. Because all modern vehicles are automatic and their systems are controlled by Engine Control Modules, the use of OBD – II has become essential, and the diagnostic process has become quite quick.

The code for the knock sensor fault is also saved as OBD – I in older automobile models. OBD – II code readers are now available on cell phones. Also, check for other defects, like, short circuits, wiring short circuits, mechanical damage to the wire, incorrect mounting, and corrosion in the wire and alongside the knock sensor.

Related Post: Replaced Knock Sensor Still Getting Code P0332, P0325, P0327

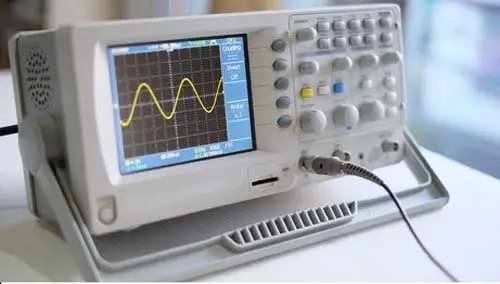

2. Testing With An Oscilloscope

The testing with the oscilloscope is performed when the engine is in running condition and it is warm. The testing procedure is given below:

- First of all, arrange an oscilloscope for the testing of the knock sensor, which must have a probe with it to connect to the knock sensor.

- Connect the testing probe with the pin of the control unit and the ground (which is the vehicle’s body).

- Now, gradually open the throttle valve.

- The graph on the oscilloscope display shows the signals with increased amplitude.

- Now, if the oscillogram is not showing the results of signals, properly, simply tap the engine cylinder near the knock sensor.

- If the knock sensor is working correctly, it will show a significant difference in the oscillogram.

- If there is not any difference in the oscillogram signals amplitude, then certainly, there will be an issue in the knock sensor.

- This no change in the graph will indicate that the knock sensor is bad and there is a need to repair or replace it.

To do regular inspection of vehicles is mandatory. Before going on the long drive, the knock sensor and the critical components must be inspected in order to avoid any uncertainty during the traveling.

Related Post: How To Test A Knock Sensor With A Multimeter

Sign Up