When the knock sensor fails, it will usually cause one or more significant symptoms. There are some methods to check whether the sensor is working correctly or not. Below, those techniques are listed which must be performed before driving the vehicle, otherwise, the consequences may be worse, and it will harm the engine if the sensor was faulty.

The testing procedure is divided into two sections. First, the inspection can be done visually just by checking the parts and observing some precautions. While the second technique includes testing via a multimeter.

What is a Knock Sensor

A engine knock sensor or detonation sensor is an electronic device that detects, diagnose, and reports a knock or engine detonation. It is found in the engine block. It is connected to the engine control module and sends a signal to vary the combustion timing and the injection timing to prevent engine damage.

Related Post: What Is Knock Sensor In A Car

Symptoms of a Faulty Knock Sensor

Here are some common symptoms of a faulty knock sensor:

- Check Engine Light

- Engine Misfires

- Engine Stalling

- Higher Emissions

- Increased Fuel Consumption

Related Post: Top 5 Symptoms Of A Bad Knock Sensor: Don’t Ignore These!

Tools Required to Test a Bad Knock Sensor with A Multimeter

Before you begin testing the knock sensor, you’ll need the following tools:

- Multimeter

- Safety Glasses

- Socket Set

- Wrench Set

- Jumper Wire

How To Test A Knock Sensor With Multimeter

- First of all, engage the handbrake and turn off the engine. Wait for the engine to be cool if it is very hot.

- Now, open the hood, then turn the engine ON after opening. It’s a precautionary measure, not to open the hood with the engine ON.

- After turning ON the engine, locate the knock sensor. It is usually found on the engine manifold, mounted beneath the intake manifold. It’s commonly fixed in the middle of the engine.

- Have your repair manual for the car, mention all the precautions while locating the sensor, to prevent possible injuries or any mishaps.

- Find the cable assembly, with the sensor. Now, disconnect it from the knock sensor by pulling it from the base of the sensor.

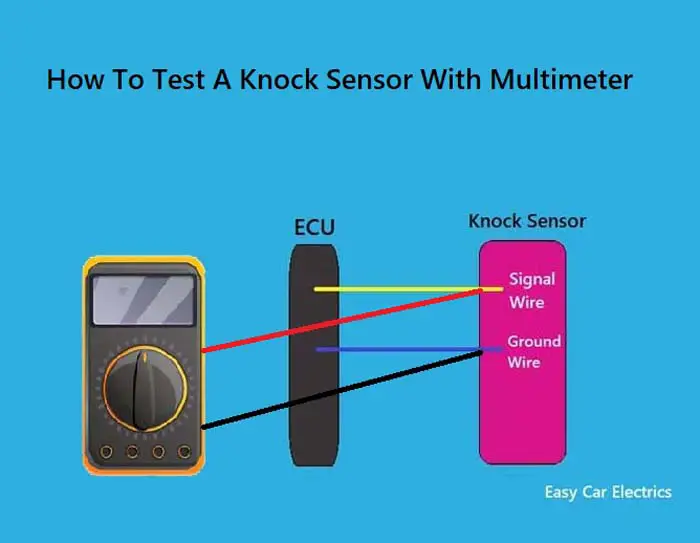

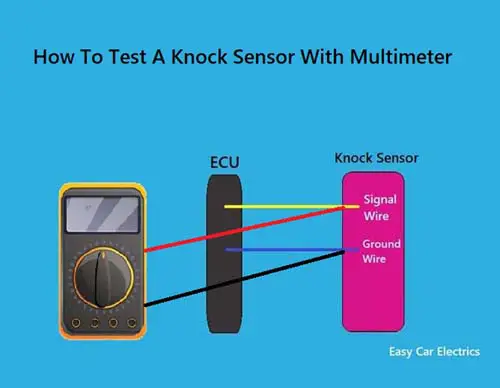

- Pick up the multimeter and connect its lead to the knock sensor. Connect the negative terminal of the multimeter to the ground point, similarly negative battery terminal.

- The measuring resistance must be seen on the multimeter if it’s working properly and has no faults. The multimeter should read resistance with a value of 93 to 110K ohms.

Doing routine maintenance is mandatory. Before going on a long drive, we recommend you check the knock sensor and the critical components to avoid unnecessary issues while traveling.

How To Test A Knock Sensor Without Multimeter

1. By Visual Inspection

I. Inspection of DTC (Diagnostic Trouble Codes):

First of all, the technique is to inspect by Diagnostic Trouble Codes. By DTC, the testing procedure will be short, as it will show each and every fault. The DTC can be found out by OBD–II, which performs testing of each component, and the diagnosis process can be easy.

As, nowadays, all vehicles are automatic and the systems are controlled by Engine Control Modules, that is why the use of OBD – II becomes crucial and the process has become very short for diagnosis. In the old car models, the code of the problems with the knock sensor is also stored as OBD – I. Nowadays, the OBD–II code readers can also be gotten on smartphones.

II. Checking for Damage in Cable Assembly:

The next process is to discuss how to check for damage in any wire associated with the sensor. The cable assembly must be checked for damage if any. From the ECM to the knock sensor, the wires must be inspected if there’s an issue. Fix that problem, and check for DTC again, if the problem shows again or not.

Also, check for other defects, like, short circuits, wiring short circuits, mechanical damage to the wire, incorrect mounting, and corrosion in the wire and alongside the knock sensor.

Related Post: Replaced Knock Sensor Still Getting Code P0332, P0325, P0327

Conclusion

Testing a knock sensor using a multimeter is a relatively straightforward process that can help you determine if this component is the root cause of your engine problems. Following the steps outlined in this article, you can check the sensor quickly and easily, saving you time and money on costly repairs.

FAQs

There are a few ways to test the sensor. One way is to use a multimeter test to measure the resistance of the sensor. Another way is to use an oscilloscope to test the output of the sensor and the third way is by doing a visual inspection. To test the sensor, disconnect the wire harness from it, and a multimeter’s used to measure its resistance.

If you hear a loud thumping or pining sound, it could be due to a defective knock sensor. You should consult your repair manual for guidance and consider replacing a bad knock sensor.

To spot the harness for a sensor, look for the point it meets the sensor. Here, it is usually located near the intake manifold.

Yes, a faulty wire base of the harness from the vehicle’s knock sensor could disrupt the current electrical path between the wire and the sensor, which could lead to a pinging engine sound and uneven fuel and air mixture. To fix this, try pulling on the harness base at the point where it meets the sensor or clips its lead to a ground point.

You should replace the sensor and engage the emergency brake and turn off the engine to avoid any accidents. Additionally, park your car on level ground. It’s important to address these issues as soon as possible to prevent any further damage to your car’s engine.

Related Post: How To Check If A Knock Sensor Is Bad? Fast & Easy Way

Sign Up