Switching from R-12 to R-134a refrigerant can seem daunting, but it doesn’t have to be. Many vehicles built in the 90s and earlier require R-12 for the A/C system, but due to environmental regulations, this type of refrigerant is banned and is no longer being produced. Fortunately, it is fairly simple to convert your vehicle’s A/C system to use R134a instead.

In this powerful guide, you will learn how to convert R-12 to R-134a system with seven quick steps, a conversion chart, and a formula.

Gather the Necessary Tools and Materials

Tools:

- AC manifold gauge set

- Vacuum pump

- R134a refrigerant can tap

- AC oil injection kit

- AC oil viscosity checker

- O-ring removal tool

- O-ring lubricant

- Safety goggles

- Gloves

Materials:

- R134a conversion kit

- R134a refrigerant

- AC compressor oil

- Replacement O-rings

- Thread sealant

- Compressed air

- Cleaning solvent

- Rag or shop towels

Please note that these are general tools and materials that are typically needed for the conversion. It’s always best to consult your car’s manual and verify the specific tools and materials needed for your particular vehicle.

Related Post: 3 Types Of Car AC Refrigerant, Freon R-12, R-134a, R-1234yf

How To Convert R12 To R134a System

R12 and R134a are air conditioning refrigerants. R-12 refrigerant was common in the past. Now it is banned due to global warming. Conversely, now the R-134a is common in the automotive industry. Before 1994, old R-12 refrigerant was mostly used in older car models. It was considered a perfect refrigerant until discovered that it causes ozone depletion.

In 1995, the Society of Automotive Engineers (SAE) changed the standard for refrigerants and made R-134a a new standard. Recently, the automotive industry is moving to another refrigerant called R-1234yf. This has very low global warming potential compared to any other refrigerant.

Now come to the point, you can convert/retrofit the system in two ways. One way is to change every part of the old car’s built system and retrofit new auto parts like the condenser, evaporator, compressor, and hose pipes. This is called the Factory Method and manufacturers recommend this method.

But, the problem is, it is a very expensive method. The switching from R12 to R134a requires the installation of a new dryer, as a fact that R134a requires a different-size dryer to function optimally. The R-134a system operates at higher pressures than R12 systems in refrigeration, but most cars manufactured after 1994 use R134a as the refrigerant. This is because the conversion from R12 to the R134a system has become quite common.

The second way to retrofit R134a in your system is the modification of existing parts if your car is old. To convert your car’s AC R12 system to R134a, only a few changes are needed, such as making the pressure ports, receiver drier, and pressure switches compatible with R-134a. To draw the refrigerant from the can, connect the blue hose to the low side port and open the system. Now below are some practical steps to convert R-12 to R-134a system.

Related Post: Car Starting System, Diagram, Working

7 Quick Steps To Convert R12 To R134a

R134a is the current industry standard for new cars, as it is more efficient and environmentally friendly than its predecessor, R12. Therefore, it is important to know how to convert r12 system to r134a. Here are the quick steps to replace the R12 with the R134a current system.

1. Discharge The R-12 Refrigerant:

- The R12 refrigerant that is currently in the system needs to be properly disposed of to minimize its harmful effects on the ozone layer.

- Empty the system from the old R12 refrigerant.

- Recover the R12 refrigerant system for recycling.

2. Flush The Whole System:

- Remove all the pag oil and contamination.

- Flush the entire system from mineral oil and debris without leaving any sign of R-12.

- Flush AC pressure lines.

Related Post: Types Of Compressor Oil

3. Retrofit The R-134a System Parts:

- Retrofit the R-134a system parts, especially the receiver drier and pressure ports.

- Because the R134a uses a larger size receiver drier and different ports for filling the refrigerant.

4. Evacuate The System:

- Attach the vacuum pump gauge and empty the system of air and moisture.

- Start the vacuum pump and then hold it for at least 45 minutes.

- Check for leaks.

Related Post: 7 Basic Parts of Car AC System

5. Charge The System:

- First of all, put the proper amount of Ester lubricating oil.

- Then, fill the system with R-134a refrigerant until you get the desired cooling.

- If you don’t know how much refrigerant to put in, you can figure out the exact amount of refrigerant by the formula mentioned below, or you can also take help from the below chart.

6. Install The Service Port Caps

- Install the low side service port cap and look.

- It is better to do a road test.

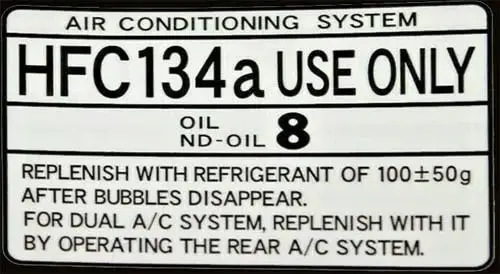

7. Attach The Warning Labels:

- Attach the retrofit label of R-134a refrigerant to warn the technician that the system has been converted to r134a.

Related Post: How Car Air Conditioner Works

Car AC R12 System To R134a Refrigerant Formula

Since R134a refrigerant is lighter than R12, means the same volume of R134a is lighter than the same volume of R12. So, it is important to know how much r134a refrigerant is to be installed while converting from R-12 charge to the R134a charge system. To exactly know how much refrigerant to install, you need to know the formula. For optimal cooling, fill the new system with 75% to 85% of its factory-set capacity to achieve the correct specs for the current system.

First, know how much the original R12 refrigerant does have your current system and multiply the r12 charge by 0.9 pounds then subtract by 0.25 pounds to get the desired value.

Formula: (R12 charge specification x 0.9) – 0.25 = Amount Of r134a Refrigerant

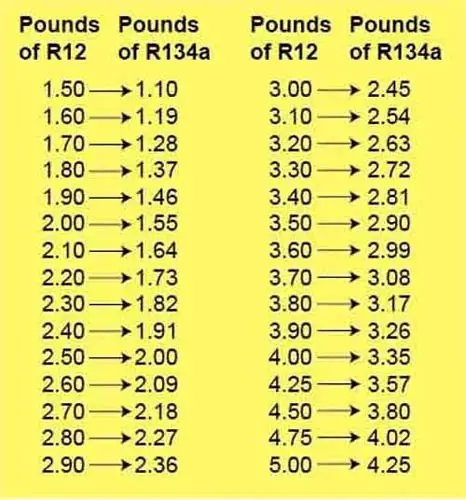

R12 To R134a Refrigerant Conversion Chart

Well on a most older cars, the r12 to r134a conversion chart serves great for the proper amount of refrigerant capacity. Below is the R12 to R134a refrigerant charge conversion chart.

Conclusion

In conclusion, converting your car’s AC system from R12 to R134a is a process that requires careful preparation. In order to properly convert your car’s air conditioning system, you need to first assess if it is safe and legal to do so in your region. You will also need to evacuate the refrigerant from the system, purchase new O-rings for the lines, re-charge the system with R134a, and use oil appropriate for this refrigerant.

If you have an older car built before 1994 and your automobile air conditioning systems have an R-12 refrigerant system. Which works fine, has no leaks, contains an average amount of refrigerant, and the system cools properly. So, you do not need to change the AC system to R-134a.

Frequently Asked Questions

To refill refrigerant using a recharge kit:

1. Connect the recharge hose to the low-pressure port.

2. Open up the system of the valve on the recharge canister and add refrigerant.

3. Monitor the pressure gauge to ensure the proper amount is added.

4. Repeat as necessary to reach the desired level.

5. Shut down the vacuum pump and turn off all three valves on the manifold gauges

When pumping out R-12 refrigerant, take precautions such as wearing PPE, properly disposing of refrigerant, using a recovery machine, avoiding heat and sparks, labeling recovered refrigerant type, completely evacuating the system, and monitoring for leaks while converting from r12 to r134a.

It can impact the refrigeration system by contributing to ozone depletion and climate change, being restricted by regulations, becoming scarce and expensive, requiring specialized equipment, and potentially affecting performance and cooling lower capacity.

The parts for the conversion kit include a blue hose and yellow hose, fittings, heat exchangers, refrigerant, oil, and a proper conversion chart to guide the process.

Technicians use a wrench to tighten connections during the modification process. Also, put the high side fitting over the old connector.

Sign Up