An oxygen sensor is a key component in a car’s emissions control system. The Oxygen sensor also called O2 Sensor or lambda sensor (λ) is an electronic sensor that detects the amount of unburned oxygen present in the discharge gas in the exhaust manifold after the combustion.

If the oxygen sensor is not working properly, it can cause the engine to run lean or run rich. A rich fuel condition can cause the engine to misfire and run poorly, which can lead to engine damage. In order to avoid this, it is important to check the oxygen/lambda sensor voltage regularly.

If you’re looking to learn more about O2 voltage in cars, then you’ve come to the right place. This informative article will tell you everything you need to know about this topic. Below is the ultimate guide on the lambda sensor’s electric pressure and the scientific reason why its voltage fluctuates.

Uncovering the Role of Oxygen Sensors in Automobiles

A lambda sensor is a vital component, located in the exhaust system. The oxygen sensor works like a fuel gauge for the exhaust gases. Its main function is to measure how much unburned oxygen is present in the vehicle’s discharge fumes and to signal the engine control module (ECM) about the air-fuel ratio.

It is designed to detect whether the fuel blend is too rich (too much fuel) or too lean (not enough fuel), which can lead to poor combustion, reduced engine performance, and increased production of harmful emissions. The lambda sensor communicates with the ECM, sending constant feedback about the air-fuel ratio to adjust it accordingly, ensuring the engine runs efficiently and produces fewer emissions. Given that, lambda sensor plays an essential role in keeping the air clean and maintaining engine performance, making it crucial for any car’s health.

Oxygen Sensor Voltage

Oxygen sensor voltage is an important factor in the functioning of a vehicle’s engine. Properly measured O2 electric pressure is essential to ensure proper fuel economy, reduce emissions, and maximize performance.

The output electric pressure from these sensors varies depending on the amount of oxygen present, so understanding how to read and interpret this electric pressure is key to proper engine management. Below is the upstream and downstream o2 sensor electric pressure measurement.

Upstream O2 Sensor Voltage.

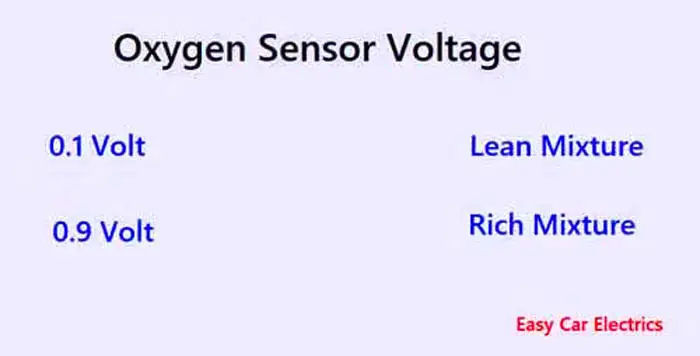

The voltage produced by the upstream O2 sensor or front o2 sensor varies from 0.1 to 0.9 V according to the discharge emission. 0.1 volt indicates a lean mixture while a voltage reading of 0.9 volts indicates a rich fuel mixture. The car runs on fuel, but the spark plug requires oxygen to create a spark in the cylinder during the combustion.

The ideal stoichiometric ratio for oxygen and fuel is 14.7:1, which means for every 1 gram of fuel consumption, 14.7 grams of oxygen is required. Maintaining this stoichiometric ratio is the duty of the ECU. The ECU maintains this ratio by taking the inputs from the sensors in the car, which is called a closed-loop system.

The upstream O2 sensor or sensor 1 takes these inputs combined with other inputs such as the MAF sensor, temperature sensor, etc, and determines the exact amount of air-fuel ratio to be sent to the engine cylinder.

The ECU works on a closed-loop system means it works on the sensor signal by constantly taking input from the lambda sensor and other sensor outputs to adjust the air-fuel ratio. This closed-loop system leads to a constant flip-flop between rich and lean.

Generally, the ECU constantly changes and corrects the air-fuel ratio from rich to lean if the fuel mixture is rich due to the variables input by the sensors. If the ECU receives a low O2 sensor signal (lean mixture), it compensates by increasing the amount of fuel in the air-fuel mixture, making it rich.

And when the ECU receives a high voltage signal (rich mixture), it reduces the amount of fuel in the air-fuel mixture, making it lean.

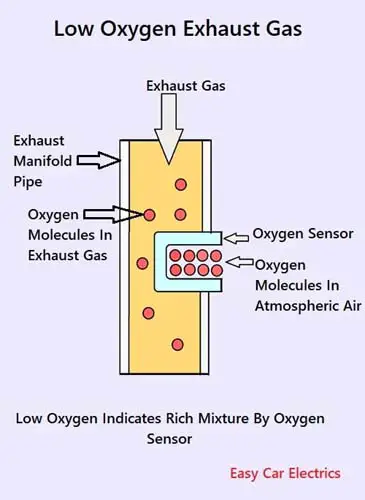

The oxygen sensor monitors how much unburned oxygen is in the exhaust system. As a rule, when the lambda detects fewer oxygen molecules in the exhaust gas after combustion, it indicates a rich fuel condition. It is because the maximum amount of oxygen is already burnt due to excessive fuel present in the engine cylinder during the combustion.

Sometimes, the ECU uses a lambda to check for proper EGR operations. The fuel-enriched mixture causes high electric pressure/voltage and will produce a maximum of 0.9 V due to the deficient amount of oxygen molecules present in the discharge fumes.

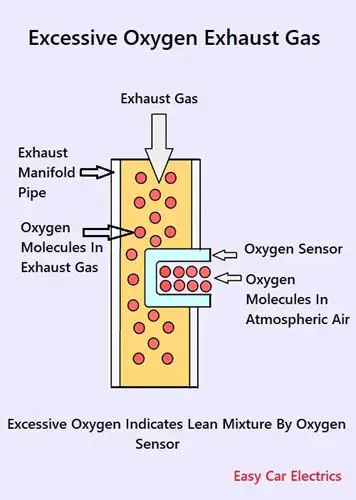

On the other hand, when the lambda sensor detects more oxygen in the exhaust emission after the combustion, it indicates that the fuel mixture is lean. It is because the fewer amount of oxygen was burnt due low amount of fuel in the cylinder during the combustion.

The lean mixture causes low electric potential/voltage and produces a minimum of 0.1 volt due to the excessive amount of oxygen molecules present in the discharge manifold.

Downstream O2 Sensor Voltage

The downstream lambda sensor, post catalytic converter O2 sensor, sensor 2, or 2nd O2 sensor is located after the catalytic converter and is used to measure the oxygen content in the exhaust gases after they have passed through the cat converter. The rear O2 sensor also monitors the catalytic converter efficiency. It produces an electric pressure/voltage signal and sends it to the sensor to regulate the fuel that is proportional to the oxygen level of the discharge gases.

In most vehicles, the downstream O2 sensor should produce a steady voltage of approximately 0.45 volts for optimal fuel or oxygen usage. If the oxygen content of the discharge gases is too high or too low after the catalytic converter, it means the cat converter is not working properly and may need to be replaced.

Scientific Reason Why O2 Sensor Voltage Fluctuate

Stick with me, here I am explaining why the voltage fluctuation occurs, why the fuel-enriched mixture produces high electric pressure, and why the lean mixture produces a low voltage.

Remember, it is all about the oxygen molecules’ concentration gap between the discharge gas and atmospheric air, the higher the concentration, the higher the voltage, the lower the concentration, the lower the voltage. The difference in the level of oxygen within the sensor causes the electric pressure/voltage to be produced.

The fuel-enriched mixture produces high electric pressure because the difference in oxygen levels is high and will produce a maximum of 0.9 V of voltage output due to low oxygen concentration. When the mixture is rich, a high amount of oxygen is burnt and less amount of oxygen will be left, so there will be a low electric pressure signal from the lambda sensor.

So, the difference in oxygen concentration between the exhaust stream and atmospheric air will be high (as you know, the atmospheric air has a high amount of oxygen) resulting in high ionization, which produces high electric pressure/voltage and the ECU will read it as a fuel-enriched mixture.

Similarly, the lean mixture causes low electric pressure and will produce a minimum of 0.1 V due to excessive oxygen. It is because a high amount of un-burnt oxygen is left after combustion in the discharge gas, the difference in oxygen concentration between exhaust gases and atmosphere air will be low, resulting in low ionization, which produces low electric pressure and the ECU will read it as a lean mixture. Hence, the lambda sensor’s electric pressure fluctuates.

Both rich or lean mixture creates pollution. According to the research, the three main discharge gas pollutants are hydrocarbons (including partially oxidized organic compounds), carbon monoxide, and nitrogen oxides.

Fuel-enriched mixtures produce hydrocarbons, and carbon monoxide while lean mixtures produce nitrogen oxides NOx, which contributes to smog and acid rain.

Related Post: What Is A Dummy O2 Sensor? You’re About To Find Out!

Importance of Oxygen Sensor

Oxygen sensors are essential components of the modern combustion engine, and federal emission laws made O2 sensors virtually mandatory. This requirement arises from the fact that these sensors enable a vehicle’s emissions control systems to accurately monitor and adjust the exhaust oxygen in order to optimize engine performance and minimize environmental degradation. Furthermore, they provide an effective means of maintaining proper combustion chamber temperatures.

The O2 sensors are used to monitor the air-fuel ratio in your engine’s discharge. This air-fuel ratio can then be adjusted to give optimal performance and reduce emissions from your vehicle using the o2 sensors.

The O2 sensor will generate a voltage signal based on how much oxygen is present in the exhaust fumes compared to the amount of fuel being consumed by the car. The sensor is mounted up and downstream of the cat converter on the discharge pipe of the vehicle. The lambda sensor starts by sensing the number of o2 molecules in the discharge gases, then the sensor causes the voltage to flow to the ECU which then rectifies the air-fuel ratio.

Signs of a Faulty Oxygen Sensor in a Car

If the O2 sensor is functioning properly, the car won’t misfire and consume more fuel, but over time the O2 sensor can become contaminated. The oxygen sensor diagnosis must be done for the sensor output electric pressure to ensure that the sensor is working properly. One of the most common signs of a faulty O2 sensor is a check engine light.

If the O2 sensor works properly there is no need to change it, You can tell if your sensor has failed by the mileage of the vehicle and the smoothness of the ride. However, if the 02 sensor is bad, then the replacement of O2 sensors is necessary. Poor engine performance is another indication of lambda sensor failure.

This is because substances might accumulate on the sensor tip of a properly functioning lambda sensor. These substances may affect the sensor and cause it

to make a bad reading. Using a scan tool, you can check the live reading of the normal operating O2 sensor for bank 1 and bank 2 sensors, and observe the sensor reading.

When To Replace The O2 Sensor

Oxygen sensors are an important component of a car’s system and should be replaced every 60,000 to 90,000 miles. While in older vehicles lambda sensors must be replaced every 30,000 to 50,000 miles.

The lambda sensor uses a heater to quickly bring the sensor up to operating temperature before it can send a signal to the car’s computer as the sensor reaches operating temperature after heating. This type of heated sensor, which typically has 3 or 4 wires, is commonly found in cars with OBD II systems.

The heated O2 sensor has its own wiring circuit, usually consisting of two wires, that are separate from the main sensor circuit. It is recommended that the unheated type used from 1995 onwards should outlast the vehicle emissions warranty. Professional replacement of O2 sensors typically costs between $50 and $100 depending on the amount of time it takes to complete the job.

Related Post: Where Is Oxygen Sensor Located: Locate O2 Sensor Easily

Conclusion

In conclusion, lambda sensors are an important component of a vehicle’s overall performance. It is essential to be aware of the up and downstream sensor voltage oscillation for optimal engine performance. Regular monitoring of the O2 sensors can help detect any abnormal behavior which may indicate a problem.

FAQs

A vacuum leak can cause an O2 sensor to set a fault code, which may trigger the check engine light to come on. The O2 sensor monitors the oxygen concentration of the exhaust gas and sends a signal to the engine management system to indicate the air fuel blend. If the air fuel mixture is not correct due to a vacuum leak, The engine control module (ECM) may use the lambda sensor to monitor the operation and set a code if necessary. The O2 sensor may set a code to alert the driver or mechanic of the problem if the issue is not resolved.

The upstream O2 sensor electric potential can vary from 0.1 to 0.9 volts, where a reading of 0.1 volts indicates a lean mixture and 0.9 V indicates a rich fuel blend. The downstream O2 sensor electric pressure should produce a steady electric potential of approximately 0.45 volts for optimal fuel or oxygen usage.

Sign Up