The crankshaft position sensor is one vital engine management component that is used to monitor the speed and position of the crankshaft rotation. The sensor is generally located near the crankshaft pulley on the engine block. The information collected by the device is used by the engine control unit (ECU) to determine the timing of ignition and fuel injection. It holds paramount importance; hence it should be kept in proper working order.

Over time, the crankshaft sensor loses its job and causes the car to stop in the mid of high way. This arises the need to fix the problem with the crankshaft position sensor. In this powerful guide, we will discuss whether it is possible to temporarily fix the bad crank sensor.

What the Crankshaft Position Sensor Is

The crankshaft position sensor is the part of the engine that monitors the position and rotational quickness of the crankshaft in an internal combustion engine. It detects the position of the crankshaft and sends signals to the engine control unit, which then adjusts engine timing and fuel injection.

The crankshaft position device is a vital component in modern engines, as it helps to ensure efficient engine operation and can also be used for diagnostic purposes.

Related Post: Crankshaft Position Sensor: How It Works, & Functions

Surprising Warning Signs of a Failing Crank Sensor

A car’s crankshaft position sensor is a critical part of its engine, measuring the speed of the reluctor’s ring to determine the rotation quickness of the crankshaft. It is responsible for determining spark timing in the cylinders and the amount of fuel injection in the car’s combustion chamber. A bad CKP device can result in several issues. Here are seven common symptoms of a broken crankshaft position sensor:

- The check engine light on the dashboard illuminates.

- The car may be difficult to start or not start at all.

- Rough idling, where the engine does not run smoothly, is observed.

- The engine misfires, causing stuttering or shaking while driving.

- Unsteady acceleration, where the car accelerates slowly, is experienced.

- The car may stall unexpectedly.

- A reduction in gas mileage is noticed.

These symptoms could indicate that the crankshaft position sensor needs replacing. To diagnose a bad CKP device, the driver can look for these signs or get the trouble codes scanned. A broken device may result from clogging due to dirt and dust or damage, which can affect the signals sent to the Electronic Control Unit (ECU) and, ultimately, affect the car’s performance.

Related Post: Top 7 Symptoms Of A Bad Crankshaft Position Sensor

Temporary Fix For Crankshaft Position Sensor

The crankshaft position sensor sends a crucial signal to ECU. If the ECU does not receive the alerts due to the CKP detector device problem, the ECU assumes that the car’s engine wouldn’t start due to a failed crankshaft position sensor

The crank sensor often becomes bad or broken due to continuous function. There are multiple device issues the crankshaft position sensor might get like issues in the device or its wiring, magnetic problems, mechanical device damage, pin and wheel problems, and a few others, which could be possible to repair.

But, when the crank detector device goes bad, it cannot be temporarily fixed unless the issue is related to a cut wire, corroded connector, or loose connection.

However, if you are away from the repair workshop, you can use remedies to start the car such as disconnecting and reconnecting the crank device connector, checking for fuel, and then trying to restart the engine.

It is almost impossible to avoid these problems, and the vehicle usually comes up with some of these issues. It is an electronic device; when it gets damaged or fails internally, it is impossible to bring it back into working.

There are no temporary fixes for the crankshaft position sensor if the device is not working. This device has to function properly at 100 percent capacity at all times, and if it’s experiencing difficulties, then the only solution is to replace the sensor with a new crankshaft position sensor.

Since repairing the crankshaft position sensor is not an option, it is necessary to replace it in order to fix the problem. It is not a good choice if you are trying to fix the CKP device on your own. Fixing a crankshaft position sensor won’t help the situation as it cannot be fixed once it’s gone bad. After replacing the faulty device, the car’s engine was running smoothly again, indicating that the issue was done with a new sensor.

Can You Drive a Car Without Crankshaft Sensor

It is generally not possible to drive a car with a bad crankshaft sensor. The CKP device is an important part of the vehicle’s ignition system and engine management system. This device watches the vehicle’s control module with information about the position and rotational crankshaft RPM, which is used to control the ignition timing and fuel injection.

If there is any problem with your crankshaft position sensor or not working properly, it can cause the engine a variety of problems, including difficulty starting the engine, engine misfires, stalling, and poor fuel economy.

In some cases, it may be possible to drive a short distance with CKP device malfunctions, but it is not recommended to drive with a broken device as it can potentially cause damage to other parts of the ignition system and engine. If you are experiencing issues with your CKP device replace it as soon as possible in order to ensure the smooth and reliable operation of your car.

Related Post: How To Bypass Crank Position Sensor: Can It Be?

Code For Faulty Crankshaft Position Sensor

The code for a faulty CKP sensor is typically P0335. This code is stored in the engine control unit (ECU) when the ECU detects an issue with the crankshaft position sensor or its circuit.

The crankshaft position sensor is a vital component of the engine management system, as it provides information about the position and quickness of the crankshaft to the ECU. This information is used by the ECU to control the ignition timing and fuel injection timing, as well as to monitor engine speed and load.

The good working of the vehicle is not possible without the CKP sensor. If the crankshaft position sensor fails or the circuit experiences an issue, it can cause problems with the engine’s performance and may trigger the check engine light. Here is the ultimate guide about P0335 Code.

Will Driving with a Bad Crankshaft Position Sensor Damage the Engine

Driving with a bad CKP sensor can potentially damage the engine, as the device is responsible for providing the engine control unit with important information about the position and rotation quickness of the crankshaft. If the device is not functioning properly, the engine may not run efficiently and could suffer from reduced performance or fuel economy.

In some cases, driving with a broken crankshaft position sensor could cause engine misfires or even engine failure. As a temporary repair, you may be able to clear any diagnostic trouble codes (DTCs) and temporarily reset the device by disconnecting the battery or using a diagnostic tool to clear the codes.

However, this will only be a momentary solution and the device will eventually need to be replaced in order to fix the problem permanently. If you are experiencing crankshaft position sensor issues then replacing it is typically the best and most effective solution.

Related Post: How To Start A Car With A Bad Crankshaft Sensor

Conclusion

In conclusion, the crankshaft position sensor is an essential component of the engine management system, providing information about the position and speed of the crankshaft to the ECU. This Broken equipment can cause several issues, such as difficulty starting the engine, misfires, stalling, and poor fuel economy.

Although there are some remedies to temporarily start the car in case of a broken device, there are no short-term fixes for a crankshaft position detector device that is not working. The only solution is to replace the old sensor with a new one. It is essential to diagnose a faulty sensor by looking for warning signs or getting the trouble codes scanned.

It is not recommended to drive with broken equipment, as it can potentially cause damage to other parts of the ignition system and engine. Thus, it is crucial to replace a broken crankshaft position detector device as soon as possible to ensure the smooth and reliable operation of the car.

Frequently Asked Questions:

If the position sensor has a problem and your car is functioning normally, as before, then you can drive for a short distance, which means that it is measuring position and rotational speed with a slight difference. However, if the engine starts to misfire then this is a sign that your crankshaft position detector device has a problem. It is time to get the sensor replaced immediately to prevent crankshaft position sensor problems.

The crankshaft position sensor monitors the position and crankshaft speed information of the engine same as the camshaft position sensor work to monitor the rotation of the camshaft and also provides information about the piston position. The crankshaft position sensor is generally considered the eye of the engine, it will not operate if the sensor is not working correctly and you will need to install the new crankshaft position device by moving the car to a mechanic shop.

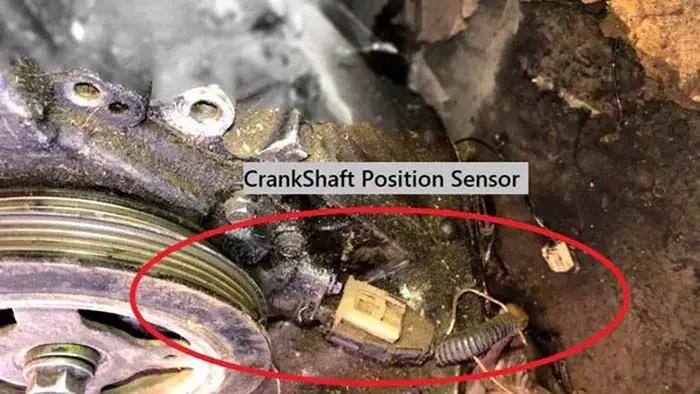

The location of this sensor is near the crankshaft pulley. You need to check near the bottom of the engine block to locate the sensor if your crank sensor malfunction because without a crankshaft position sensor, ECU will not receive data about the piston position and crankshaft speed. Identify whether the issue is of the position sensor or its wiring; depending upon whether you are using a 2-wire sensor or a 3-wire sensor(most commonly two types of crankshaft sensors). It is of utmost importance to replace the crankshaft position sensor to prevent any miscommunication between the crankshaft and the engine control unit.

This sensor is usually manufactured to work for a very long time, however, if the vehicle is facing starting difficulties or showing a check engine light then you might experience issues with your crankshaft position sensor. The crankshaft sensor monitors important information so without the crankshaft position sensor your vehicle even might not start. In such conditions either bypass the crankshaft detector or replace it with a new sensor and ensure that the new sensor is working properly.

If the vehicle is experiencing a crankshaft position device problem then the engine might refuse to start. Under such circumstances, if the car is still running this means that ECU is using inaccurate data to optimize its performance in such case crankshaft position detector could cause permanent damage to the engine. This detector is part of the engine management system that runs the vehicle so we need to replace the crankshaft detector immediately.

Sign Up