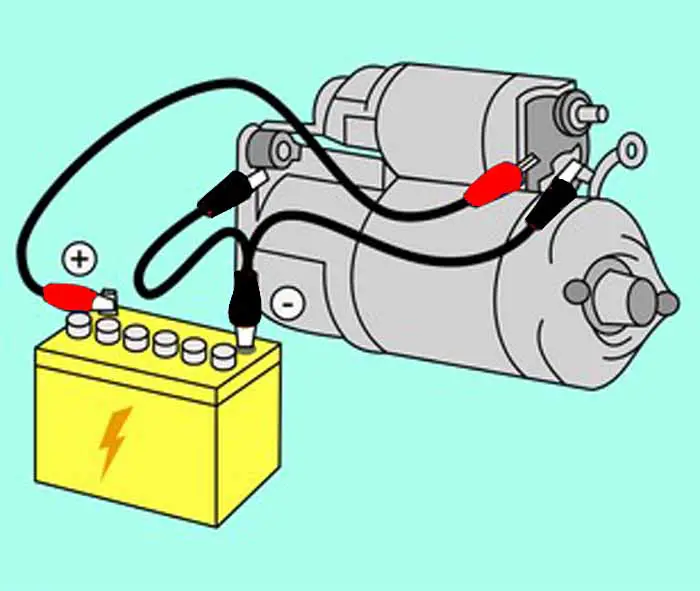

The starter motor is a device used to start the engine. It is an electric motor that turns the car’s engine over to start it. The starter motor is powered by the car’s battery. When you turn the key in the ignition, the starter motor turns the engine over and starts the car.

In a typical car, the starter motor is located near the front of the engine and is connected to the battery and to the flywheel. The starter motor contains a small electric motor that turns a gear, which in turn engages the flywheel. This action causes the engine to turn over and start.

It comes with different variations and designs. Below are the two most common types of starter motors used in modern vehicles. Read on to know the different types of automotive electric starter motors in a few minutes.

Related Post: How A Starter Motor Works

Types Of Starter Motor

2 Types of Automotive Starter Motor

An internal combustion engine can be started by either a hydraulic, pneumatic, or electrical starter motor, but the most common one is an electric starter motor.

The first electric starter motor was considered a breakthrough in the vehicle world, even though there was plenty of room for improvement. As technology has advanced, motor manufacturers have developed better electric starter motors that consume less power and produce more torque.

There are many types of vehicle electric starter motors such as inertia starter motors, and Folo-Thru drive starter motors, but a modern vehicle electric starter motor comes with MAIN two types, which go head to head according to the demand and application of the vehicle.

- Direct Drive Electric Starter Motor

- Gear Reduction Type Starter Motor

These are the two most common types of vehicles electric starter motors are used especially in gasoline and diesel engines. Moreover, there are subcategories of these two types, which have construction and design variations such as the use of the permanent magnet, field coil, overrunning clutch, etc.

A direct drive or gear reduction type starter motor can come with different designs. Below are the different variations and versions of the two main types of vehicle electric starter motors.

- Permanent Magnet Direct Drive Starter Motor

- Permanent Magnet Gear Reduction Starter Motor

- Field Coil Direct Drive Starter Motor

- Field Coil Gear Reduction Starter Motor

These variant vehicles’ electric starter motors come with different extra features and development, such as Pre-engaged style, nosecone or nosecone-less version, and drive assembly with Overrunning Clutch.

In most cases, they are custom-designed for Light, Medium, and heavy-duty applications. Now before I explain starter motor types, first you need to know a few terminologies which will help you understand the topic well.

Related Post: 11 Parts Of Car Starter Motor & Functions

Speed:

It means how fast or slow a shaft rotates. A fast-rotating shaft has a high speed and while a slowly rotating shaft has a low speed. It is the rate at which a shaft rotates, in other words, it is the number of rotations per minute. Its unit is RPM (revolution per minute).

Torque:

A force is simply a push or a pull, while torque is a twisting force, which means torque is a rotational push or pull. As force causes linear straight motion but, remember the torque causes rotational or angular motion. Its unit is Newton meter.

Relationship between Speed And Torque:

The above definition I wrote to help you better understand the relation between speed and torque. It is very important to know this relationship so, that you understand well the types of starter motors in the coming topics.

You should know the relation that the torque and speed are inversely proportional to each other. It means when the rotating shaft speed is high, it will produce less torque, and similarly, when the rotating shaft speed is low, its torque will be high. The reason is that the ability of the shaft to produce torque slowly decreases with an increase in speed.

You can notice this relationship in the car while driving up on steeps. You put the car in a lower gear rather than in a higher gear. It is because, at lower engine speeds, the torque of the engine is high and can smoothly go up inclines. While at a higher engine speed, the engine cannot produce enough torque and cannot go uphill.

So, I put the whole introduction for showing you understand the types of starter motors. Here is just a review of starter motor types, which will be deeply explained in the next point.

In a direct-drive starter motor, the pinion gear speed is high that’s why its torque is low. And in a gear reduction-type starter motor, the pinion gear speed is slow through a mechanism called reduction gear through which higher torque is achieved.

Keep these points in mind, it will help you understand the types of starter motors in the coming points.

1. Direct Drive Starter Motor

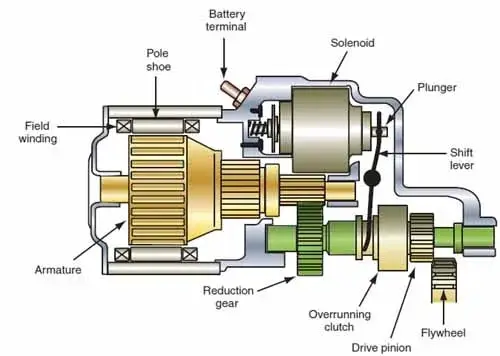

A direct drive starter motor also known as a DD starter motor is a type of vehicle electric starter motor in which the armature is directly connected to the pinion gear. Due to this mechanism, the pinion gear transfers the armature force directly to the engine flywheel.

In other words, you can say the armature and pinion gears are placed straight in-line position without having an additional gear fitted in the middle of them like planetary or reduction gear.

The direct drive starter motor is the long-used starter motor in vehicles. It is the conventional type of starter motor that is heavier and bigger in size. Furthermore, it gives a 1:1 gear ratio, which means with each rotation of the armature the pinion gear rotates one time.

You need to know that a car needs a massive amount of torque to turn the crankshaft. For this reason, the starter motor was built bigger in size which consumes a lot of electricity, and even on a weaker battery, it could not start.

According to Elreg, a direct drive starter motor uses up to 50 percent more electrical power to start the engine than a gear reduction starter motor. Due to this reason, it needs high-current battery cables and other accessories to carry the current.

Generally, a vehicle needs a lot of torque to turn ON the engine. It has to rotate the crankshaft, the camshaft, the valves, pistons, the timing gear, the power steering pump, the alternator, etc. Furthermore, in a diesel engine, especially on cold days it becomes even more difficult for the starter motor to compress the high air-fuel ratio. That’s why the direct drive starter motor is bigger in size and needs a lot of power to crank the engine.

Here, one drawback you should keep in mind about the direct drive starter motor is, that it does not have an excellent cold crank capability, especially with low current, although its armature is heavier and bigger in size still, it produces low torque at the pinion gear.

Therefore, engineers needed to design a starter motor that can have excellent cold crank capability with low current. So, they are compelled to invent a starter motor that is light, stable, small, and efficient. Hence, the existence of the gear reduction starter motor came into being.

Related Post: Starter Motor Diagram

2. Gear Reduction Starter Motor

In 1962 Chrysler first introduced the gear reduction type starter motor, they designed a set of gears in between the armature and pinion gear. A gear reduction starter motor is a direct drive starter motor with an additional gear set fitted in the middle of the armature and pinion gear on the same axis. This additional gear set can be either planetary or reduction-type gear.

Now before I step further, I need to explain the misconception about the term gear reduction. Gear reduction, usually from meaning you would consider that the gear size is reduced. It is somehow right. But, here in a vehicle starter motor, the meaning is taken differently. In a starter motor, gear reduction refers to an arrangement of gears in which the output gear ratio is reduced and slower gear speed is achieved.

In other words, you can say gear reduction refers to the reduced speed of the pinion gear in the vehicle starter motor. So, gear reduction starter motors use gears to reduce the output speed of the starter motor and increase the torque (Crank Capability). This type of starter motor uses extra gear in between the armature and pinion gear.

This is important to know that gear reductions are achieved by many designs but two types of designs are more popular in a vehicle’s electric starter motor. The following are the two types of designs to achieve gear reduction.

A: Offset Gear Reduction

B: Planetary Gear Reduction

A: Offset Gear Reduction

In the off-set gear reduction starter motor, an extended spur gear (Straight-cut Gear) meshes parallel to the pinion gear. This extra gear reduces the pinion gear speed by four times of original speed and achieves more torque (Cranking Power) than a direct drive starter motor.

In the reduction gear starter motor, the armature and pinion gear are not in line. They both are placed on different axis. The armature drives the reduction gear, the reduction gear drives the pinion gear.

B: Planetary Gear Reduction

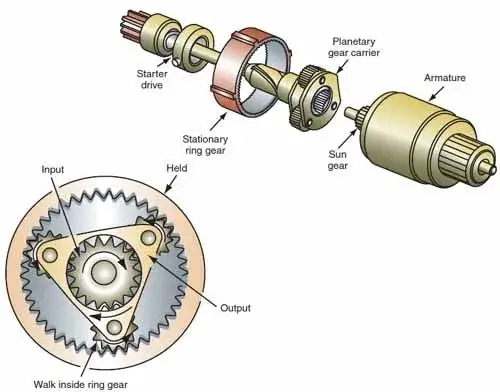

The second way to achieve a gear reduction is by using a planetary gear set. A planetary gear set is a collection of gears enclosed in a case, used to achieve a reduced pinion gear speed and increased torque.

A planetary gear set performs the job of a reduction gear, which reduces the speed of the pinion gear. It is placed between the armature and pinion drive on the same axis. The main benefit of planetary gear assembly is that it is light, compact, efficient, and so smaller that you wouldn’t recognize it from the outside.

Also, it allows for a significantly smaller starter motor that is light in weight but produces high torque without having to increase the size of the starter motor. Now let me clarify the working operation of the planetary gear reduction starter motor.

The armature gives the input to the planetary gears through the sun gear, and the planetary gear gives the output to the pinion gear via planet gears. Here is what I mean, the planetary gear assembly takes a high-speed, low-torque input from the armature and makes it increase its torque and reduces the speed at the output pinion gear.

It is designed to produce a gear ratio of 4:1, which means with each rotation of the pinion gear, the armature shaft rotates four times. Let me elaborate further on this point by taking you to the earlier point that, the gear reduction means the low speed at the output gear of the starter motor.

The planetary gear gives the ratio of 4:1. Now, if you look at it here, a gear reduction is achieved with a ratio of 4:1 by planetary gear, which means the pinion gear speed is reduced four times.

So, you can say the planetary gear acts as a reduction gear that reduces the speed and produces high torque at the output. Ok, so, it was all about planetary gear reduction type starter motor. A reduction gear is the best choice for a car company.

Indeed, I earlier described the relation between speed and torque, when the speed is reduced, the torque is automatically increased. Similarly, the planetary gear does this job which decreases the pinion gear’s rotational speed and increases the torque.

As its armature has a smaller size, that’s why it draws less battery current and produces enough torque on a weaker battery. Apart from that, it is stable, efficient, and almost twice as light as a direct-drive starter motor, this is the reason, it dominates the direct-drive starter motor in the vehicle.

Moreover, a gear reduction starter motor has the excellent cold crank capability with a low current drain from the battery even with a weaker battery, and almost produces four times more torque than a direct drive starter motor does. Because of this, it is well suited for diesel engines and other high-compression engines. That’s why the direct drive starter motors are slowly being replaced by a reduction gear starter motor.

Sign Up